02 Jun 2017

One of my favourite parts of art school was the infrequent "one day brief", in which everyone would turn up early in the morning, be given a project to work on for the day, and then hand in work for presentation that evening. Rather than deliberating and procrastinating for weeks over a longer term project it was a good opportunity to just get out here and actually do something.

In that spirit, I booked yesterday off work with the aim of starting and completing a project in one day, utilising the facilities of Leeds Hackspace. The weather has actually been quite nice recently, so I decided to make a simple device to indicate when it was most dangerous to be in the sun - a visual representation of the UV index for Leeds - as I've found myself getting close to catching the sun when walking home from work.

Continue reading...

05 Mar 2017

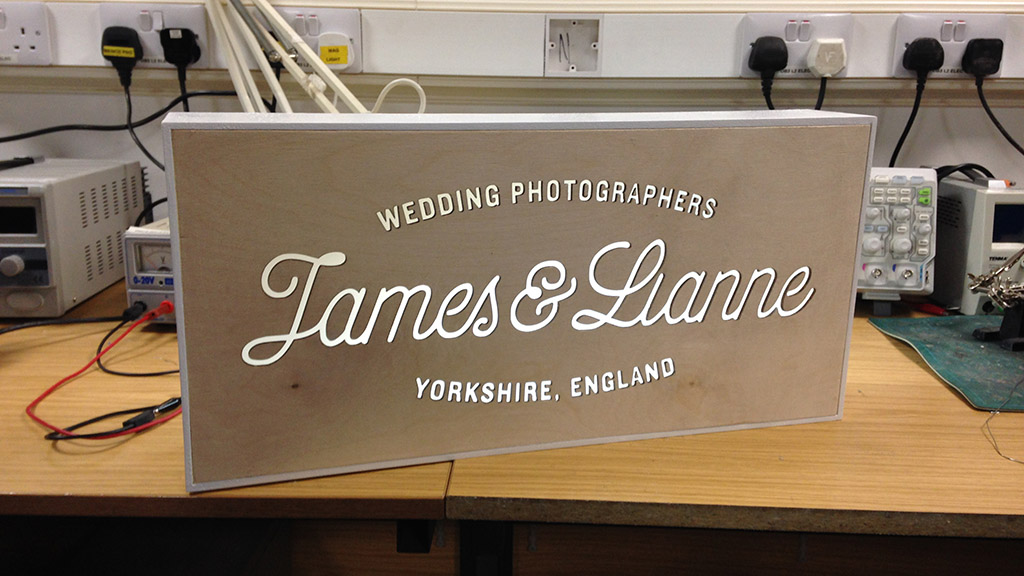

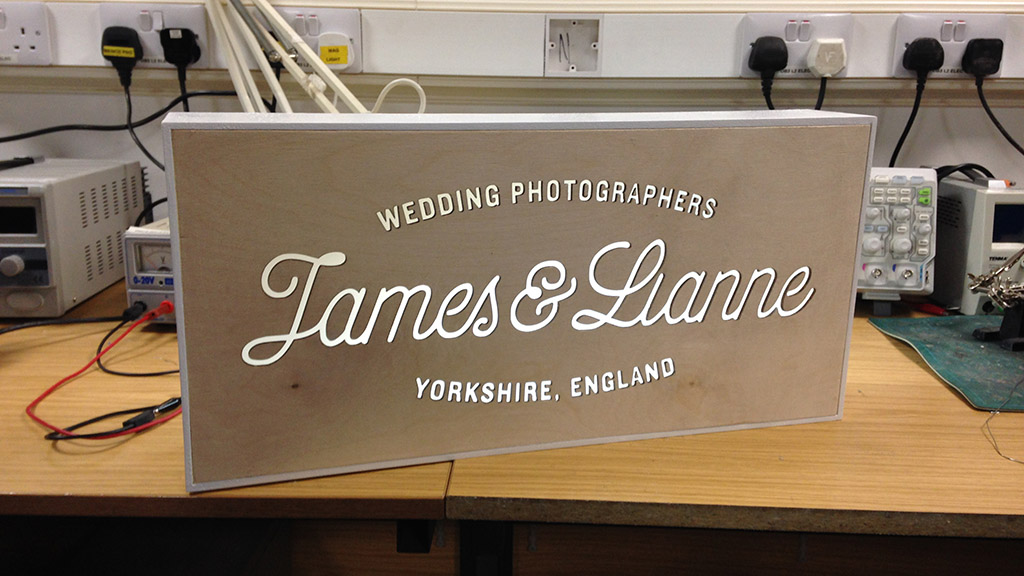

Local wedding photographers and long time friends James and Lianne asked me to build an illuminated sign that they could take to trade shows and

wedding fairs. A vector file was provided with the company logo, and the design was

laid out in Fusion 360 prior to cutting to provide an idea of what the finished

sign would look like.

The wooden face was cut from plywood on the Laser Cutter at Leeds Hackspace. The counters are held in place on the frosted acrylic backing with epoxy. The frame was built from scrap MDF, sealed with MDF sealant and then painted white.

Continue reading...

12 Dec 2016

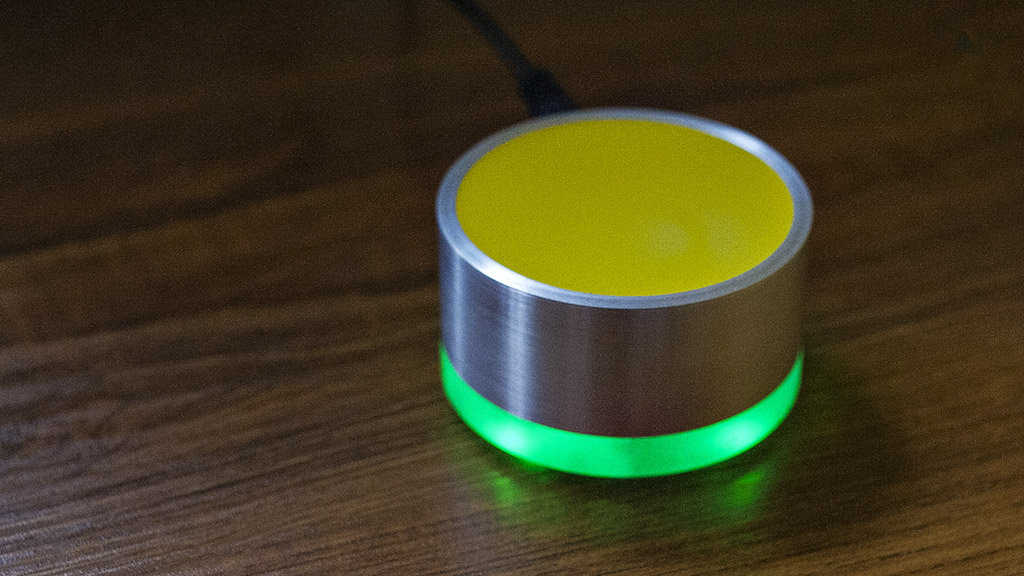

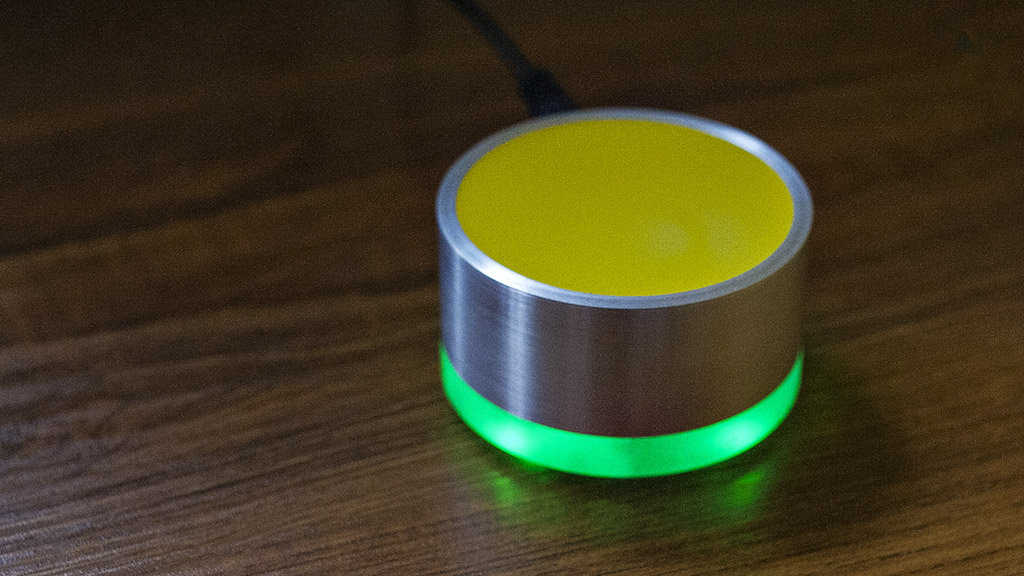

With the aim of promoting involvement and upward mobility within Leeds Hackspace I created OpenBot - a small device which tweets how long the space will be open to members for.

With a simple twist of a knob and push of a button OpenBot will shout to the world how long the space will be open for - and thus open to all members, keyholder or otherwise.

Continue reading...

20 May 2016

A quirk of small Boxford CNC lathes is that, contrary to what appears to be most other CNC turning machines, they use their back-side tooling the "right" way up - with their insert facing away from the bed. This gives the advantage of allowing the user to see the tool edge clearly but also has the critical disadvantage that it requires left-hand oriented tools.

Typically this isn't an issue. Normal turning tools are available readily in left and right handed versions, but when it comes to specialist tooling (like those used for threading) things can start to get very expensive, very quickly.

Continue reading...